Special-Purpose Machine Design: Merging Form and Function

10 May 2024

Reds Engineering creates bespoke solutions for diverse industrial applications with special-purpose machine design. Explore the process behind this service.

Special-purpose machine design merges form and function to drive functionality and performance in diverse industrial settings. Usually, special-purpose machines play a pivotal role in various industries, offering tailored solutions to unique manufacturing challenges. These machines are meticulously designed to perform specific tasks with precision, efficiency, and reliability. From automotive assembly lines to pharmaceutical packaging, special-purpose machines are custom-built to meet the exact requirements of a particular production process.

The Significance of Custom Solutions

Every manufacturing operation is unique, with its own set of requirements, constraints, and objectives. Off-the-shelf machinery may not always align perfectly with the specific needs of a production process, leading to inefficiencies, quality issues, and increased downtime.

Special-purpose machines address this challenge by offering custom solutions tailored to the exact specifications of a particular application. By designing machines from the ground up to suit a specific task, Reds Engineering can optimise workflow, enhance product quality, and improve overall efficiency.

Now, successful special-purpose machine design often involves collaboration between engineers, designers, technicians, and end-users. By working closely with clients to understand their unique requirements and challenges, Reds Engineering can develop solutions that address specific pain points and deliver tangible benefits. Additionally, leveraging our expertise in various domains, such as robotics, mechatronics, and materials science, enhances the design process and enables the integration of state-of-the-art technologies into the final product.

Key Considerations in Machine Design

Designing a special-purpose machine requires a comprehensive understanding of the manufacturing process it will be employed.

Therefore, we carefully assess factors like production volume, cycle time, material handling requirements, and quality standards to develop a solution that meets the client’s needs. Moreover, considerations like ergonomics, safety, and ease of maintenance are vital aspects of machine design. Incorporating them into the design process allows us to create machines that not only perform optimally but also prioritise the well-being of operators and maintenance personnel.

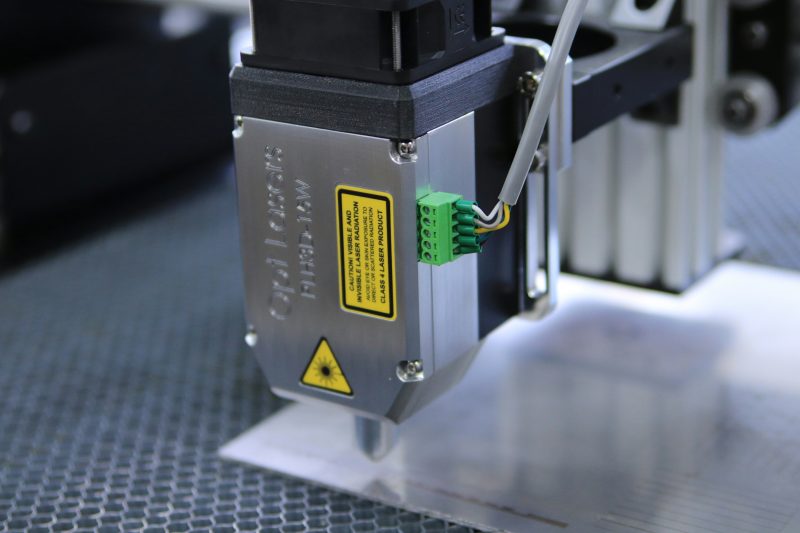

Advancements in technology have then revolutionised the field of special-purpose machine design, enabling the creation of highly sophisticated and versatile solutions.

From robotic automation to advanced sensor systems, modern machines leverage cutting-edge technologies to improve accuracy, speed, and flexibility. For instance, vision systems can be integrated into special-purpose machines to enable real-time quality inspection and error detection, ensuring that only flawless products proceed down the production line. Similarly, the use of programmable logic controllers or PLCs and customised software allows for precise control and monitoring of machine operations, enhancing efficiency and responsiveness.

Special-Purpose Machines: Applications

Special-purpose machine design by Reds Engineering can serve many industries.

The automotive industry, for instance, can take advantage of special-purpose machines for conducting tasks like welding, assembly, and inspection in automotive manufacturing plants, improving efficiency and quality while reducing labour costs. Customised machines for slicing, dicing, and packaging can then enhance productivity and consistency in food processing facilities, ensuring compliance with strict hygiene and safety standards. Lastly, pharmaceutical manufacturing can maximise special-purpose machines for filling, capping, and labelling, enabling precise and efficient production of pharmaceutical products and meeting stringent regulatory requirements.

Optimized by: Netwizard SEO