Milling Services Melbourne: The Key to High-Quality Gear and Component Fabrication

08 July 2025

Milling services Melbourne underpin the manufacturing of precision gear and componentry, offering reliable solutions for complex industrial requirements. Cutting-edge processes facilitate consistent results, enhancing efficiency and quality in gear and part fabrication for Australian industries.

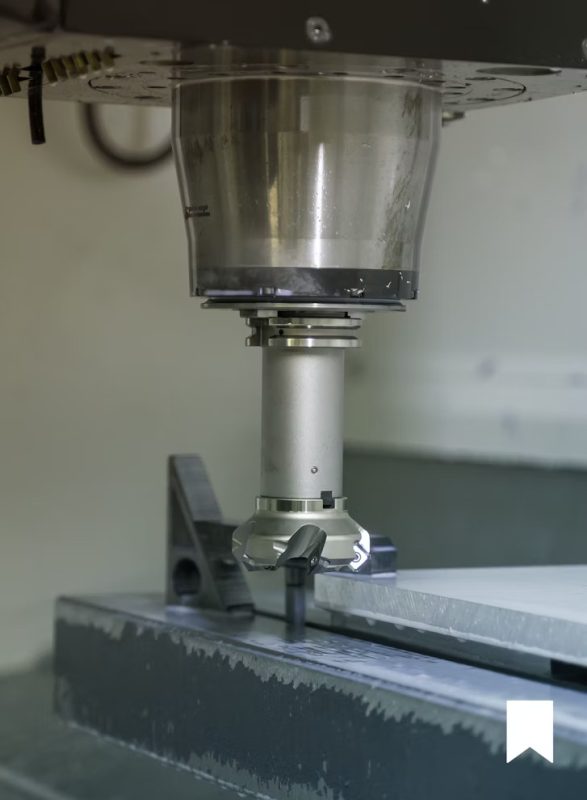

Milling Services: Precision for Modern Manufacturing

Delivering exacting accuracy, milling solutions ensure every fabricated component meets specific dimensional standards. Sophisticated equipment enables consistent production outcomes, vital for sectors where reliability and repeatability are required. Processes prioritise error minimisation, supporting seamless integration of machined parts into larger assemblies.

Industries demanding rigorous compliance benefit from structured methodologies applied throughout each stage of machining. Standardised practices assist businesses in achieving regulatory and operational benchmarks.

Advanced Techniques for Gear Fabrication

Modern gear production demands technical accuracy and process innovation. Precision machining utilises advanced methods that deliver dependable gear quality and consistent results.

Key gear milling techniques include:

• CNC milling: Automated controls produce intricate gear profiles, reducing the risk of human error.

• Surface finishing: Advanced techniques improve surface hardness and reduce friction, extending operational lifespan.

• Precision tooling: Customised tools create exact tooth geometries, guaranteeing reliable gear engagement.

• Material versatility: Processes adapt to diverse alloys, supporting tailored solutions for different applications.

• Batch inspection: Rigorous quality checks validate every gear’s accuracy before integration into assemblies.

Tailored Solutions for Diverse Industry Needs

Diverse industries require adaptable manufacturing approaches to address unique operational challenges. Component fabrication services provide customised solutions that align with specific sector requirements.

Diverse applications are addressed through:

• Automotive component machining: Manufacturing driveshafts, gears, and engine parts to tight tolerances.

• Mining equipment fabrication: Producing wear-resistant components for demanding mining environments.

• Agricultural implement production: Creating robust parts for reliable machinery operation in the field.

• Aerospace hardware creation: Machining structural elements that demand superior precision and durability.

• Marine equipment manufacturing: Delivering corrosion-resistant fittings and mechanical assemblies.

• Energy sector componentry: Producing parts for turbines and heavy-duty electrical systems.

• Industrial plant solutions: Supplying custom machine parts for continuous plant operations.

Precision Manufacturing with Reds Engineering

Consistent adherence to industry standards enables Reds Engineering to deliver dependable milling operations for precision gear and component fabrication. Advanced capabilities and a focus on quality establish us as a preferred provider for intricate industrial parts and assemblies.

Contact us to learn how our specialised milling solutions meet your manufacturing requirements and contribute to successful project outcomes.

Related Blog: Precision CNC Milling Services: Achieving High Tolerance and Superior Quality in Manufacturing

Optimized by: Netwizard SEO