Aluminium Fabrication in the Food and Beverage Industry

12 June 2024

Discover the advantages of aluminium fabrication for food & beverage equipment in Australia. Reds Engineering delivers high-quality, hygienic solutions.

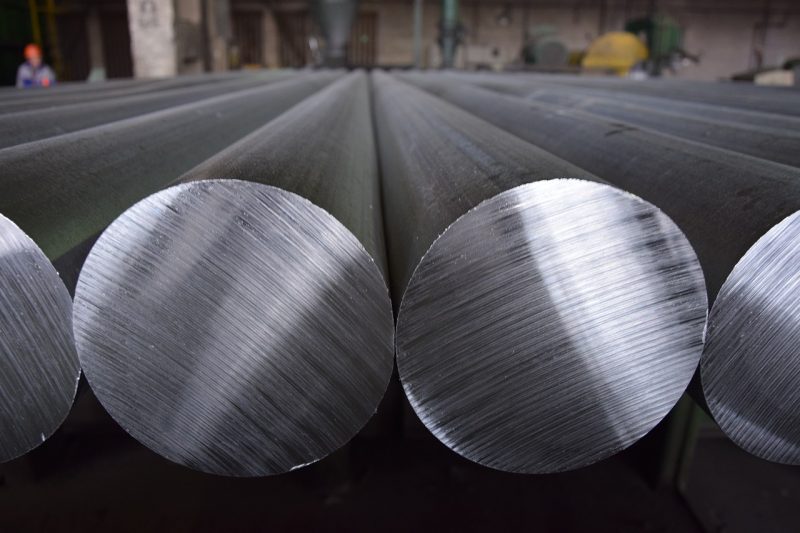

Behind the scenes, aluminium plays an important part in Australia’s food and beverage industry. Its superior workability, corrosion resistance, and lightweight strength make it a top option for fabricators creating equipment for anything from processing dairy products to brewing beer.

At Reds Engineering, we understand the particular requirements of the food and beverage industry, together with our proficiency in aluminium fabrication, we guarantee that the equipment you receive is long-lasting, dependable, and safe.

Why Aluminium?

While stainless steel often takes centre stage, aluminium offers several advantages that make it a compelling choice for many food and beverage applications:

• Lightweight: Compared to steel, aluminium boasts a significantly lower weight. This translates to easier handling, reduced strain on support structures, and potentially lower transportation costs.

• Corrosion Resistance: Aluminium naturally forms a protective oxide layer that shields it from corrosion. This is especially important in food production environments where frequent cleaning and sanitization are essential.

• Workability: Aluminium is highly malleable and ductile, allowing for intricate shapes and bends during fabrication. This flexibility enables the creation of custom equipment precisely tailored to your specific needs.

• Heat Conductivity: Aluminium excels at transferring heat, making it ideal for applications involving temperature control, such as heating kettles or cooling tanks.

• Hygiene: Aluminium is non-porous and smooth, facilitating thorough cleaning and minimizing the risk of bacterial growth. This is crucial for maintaining food safety and regulatory compliance.

Aluminium Fabrication Applications in Food and Beverage

The versatility of aluminium fabrication allows it to shine in a wide range of food and beverage settings:

• Brewing and Distilling: Aluminium tanks, vats, and fermenters play a vital role in beer and spirit production. Their lightweight nature makes them ideal for large-scale brewing operations.

• Dairy Processing: Aluminium is commonly used for milk storage tanks, pasteurization equipment, and pipelines due to its excellent hygiene properties and resistance to corrosion from acidic milk products.

• Beverage Canning and Bottling: Aluminium is the go-to material for beverage cans due to its lightweight strength, recyclability, and ability to maintain product integrity.

• Food Processing Lines: Aluminium fabrication creates essential components like conveyor systems, hoppers, chutes, and storage containers, ensuring efficient and hygienic food processing.

• Commercial Kitchens: From countertops and shelving to cooking utensils and storage solutions, aluminium offers a hygienic and durable option for busy kitchens.

Reds Engineering: Your Aluminium Fabrication Partner

Reds Engineering is committed to providing the food and beverage industry with top-notch aluminium fabrication solutions. In close collaboration with you, our skilled team of engineers and fabricators develops equipment that satisfies the strictest requirements for hygienic design, practicality, and longevity.

We use cutting-edge fabrication methods, including welding, shaping, and cutting, to make unique items that fit well into your current manufacturing process. We also give top priority to food safety and adherence to regulations. We ensure that all of our welds adhere to the highest hygienic requirements and utilize food-grade aluminium.

For your food and beverage operation, aluminium fabrication delivers an outstanding mix of strength, portability, and hygiene at a low weight. Discuss with us about your project and find out how Reds Engineering’s specially crafted aluminium equipment may assist you in achieving the best possible food production.

Optimized by: Netwizard SEO