CNC Machining Melbourne: Optimising Packaging Lines with Precision Parts

06 June 2025

Enhance packaging performance using CNC machining in Melbourne by Reds Engineering to achieve precision, reliability, and boost production efficiency.

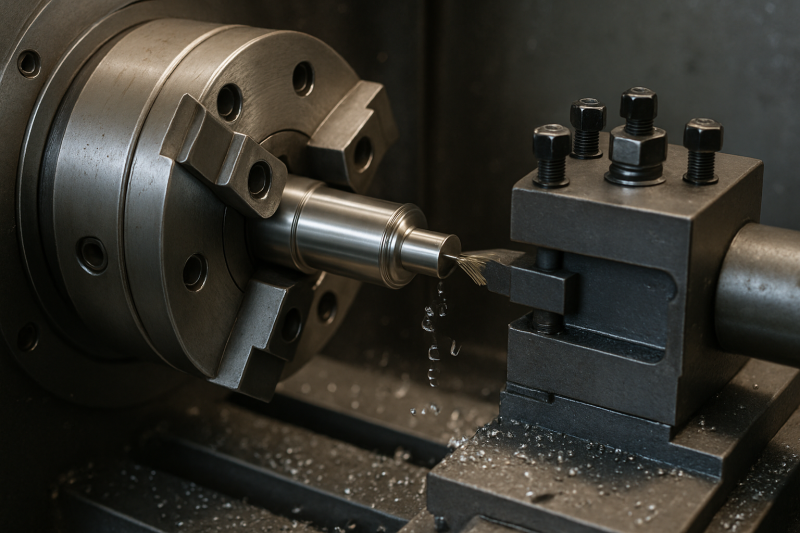

CNC machining delivers measurable outcomes in packaging line performance by enabling the manufacture of highly accurate components. CNC manufacturing in Melbourne services offer unmatched repeatability and dimensional stability, improving throughput and maintaining equipment reliability throughout the production lifecycle.

CNC Machining Solutions for High-Speed Packaging Lines

Packaging lines demand absolute coordination among their mechanical components. CNC-machined parts ensure proper alignment, reduce vibration, and maintain high-speed performance even under heavy operational stress.

Material feed systems, sealing arms, and guiding rails manufactured through CNC processes retain their geometrical integrity over extended use. These qualities reduce unscheduled maintenance and increase uptime in fast-paced manufacturing environments.

Sustainability Benefits of CNC Machining in Packaging Lines

Machining techniques that employ precise cutting paths minimise raw material usage. CNC systems limit overproduction, contribute to efficient batch sizes, and eliminate unnecessary energy use.

Tight tolerances reduce material waste during assembly and enhance the overall performance-to-weight ratio of packaging machinery. Lifecycle extension of parts delays component replacement, creating long-term sustainability gains across operational schedules.

Driving Innovation in Melbourne Packaging via CNC Machining

Machining technologies used in Melbourne continue to foster advancements in packaging design. CNC processes assist manufacturers in validating concept layouts, producing low-volume trials, and integrating automation-ready enhancements for scalable production.

• Faster Turnaround for Prototyping: Machined parts provide accurate representations of final production components. Adjustments based on early prototypes reduce errors and improve manufacturability in scaled phases.

• Improved System Adaptability: Packaging lines built with custom-machined elements adjust easily to varied container shapes and sizes. This flexibility enables manufacturers to service niche markets efficiently.

• Enhanced Component Compatibility: CNC-milled interfaces align seamlessly with automated actuators and conveyors. Consistency in dimensions across batches enables smoother synchronisation.

• Refined Automation Integration: Robotics systems achieve better accuracy when mounted on precise fixtures. Machined mounts ensure proper alignment, helping systems respond accurately to digital instructions.

• Reduced Assembly Rework: Fitting errors and manual adjustments decrease when machined parts match digital specifications. Assembly time shortens and product output gains reliability.

Precision-Led Productivity: Enhancing Packaging Operations

Through innovation and technical discipline, Reds Engineering contributes to Melbourne’s packaging efficiency using precision machining. Our capability to develop packaging systems that improve speed, reduce waste, and integrate scalable automation reflects the manufacturing strength embedded in every component produced.

Partner with Reds Engineering to secure consistent output through engineered precision.

Improve production efficiency to learn how precision machining enhances performance with this blog: Production CNC Machining: Everything You Need to Know

Optimized by: Netwizard SEO