The Role of Prototype Manufacturing in Identifying Design Flaws Early

28 November 2024

Reds Engineering specialises in prototype manufacturing to identify design flaws early, ensuring improved product quality and cost-efficient development.

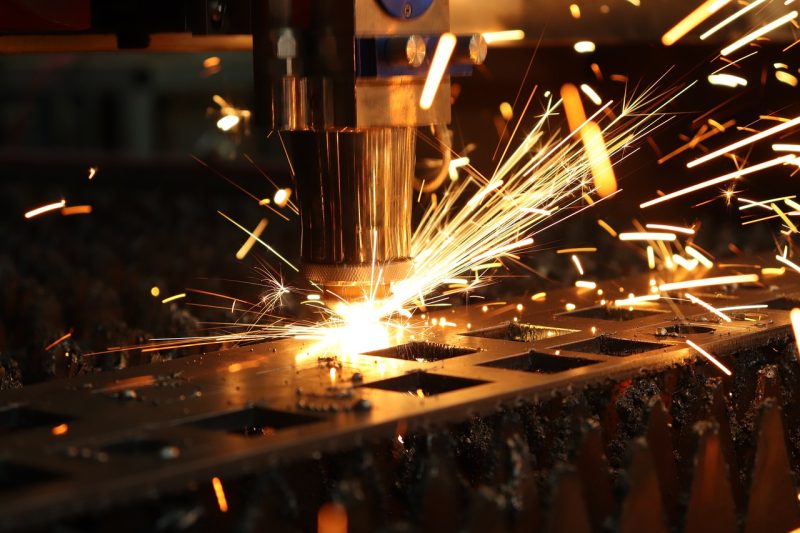

Prototype manufacturing assists in the product development process by enabling teams to identify design flaws early on. By creating physical models of products, designers and engineers can conduct functional tests, gather user feedback, and assess usability before full-scale production begins.

What is Prototype Manufacturing?

Prototype manufacturing refers to the process of creating a preliminary version of a product, known as a prototype, to evaluate its design, functionality, and manufacturability before full-scale production. This process plays a crucial role in product development across various industries.

Some key purposes of prototypes are as follows:

• Testing and Validation: Prototypes are used to test the design and functionality of a product, allowing engineers and designers to identify potential issues early in the development process. This helps in validating concepts, features, and specifications before committing to mass production.

• Design Iteration: Creating prototypes allows for iterative design changes. Feedback from testing can be incorporated into subsequent versions, which leads to improvements in the final product.

• Demonstration: Prototypes serve as tangible representations of ideas, enabling stakeholders, investors, or potential customers to understand the product concept better. This is particularly important for securing funding or market validation.

Identity Design Flaws with Prototypes

Identifying design flaws during prototype manufacturing is a critical step in the product development process. Prototyping allows engineers and designers to evaluate and refine their concepts before full-scale production, reducing the risk of costly mistakes.

Here’s how prototype manufacturing helps in identifying design flaws:

• Functional Testing: Prototypes allow for functional testing under actual operating conditions. This helps identify issues related to performance, usability, and reliability that may not be apparent during the design phase. Involving end-users in testing can also reveal practical challenges and flaws that designers may not have anticipated.

• Design Iteration: Techniques such as 3D printing enable quick iterations, allowing designers to test multiple versions of a product efficiently, uncover design flaws, and facilitate rapid adjustments based on feedback. By creating different prototypes that vary in design features, teams can likewise compare and identify which elements work best, leading to better-informed design decisions.

• Visual and Structural Evaluation: Prototypes allow designers to assess the visual aspects of a product, ensuring it meets aesthetic and branding requirements. Flaws related to design aesthetics can be identified and corrected early. Additionally, physical prototypes enable the testing of materials and construction techniques to evaluate strength, durability, and safety. Issues such as weakness, instability, or wear can be detected before full production.

• Ergonomics and Usability Assessment: Prototypes help evaluate ergonomics by allowing real users to interact with the product. This can reveal design flaws related to comfort, accessibility, and ease of use, leading to improvements in user experience. Testing prototypes can even identify inefficiencies in design that hinder user performance, prompting essential adjustments.

• Compliance and Safety Verification: Prototypes can be tested against industry standards and regulations to ensure compliance with safety and quality requirements. Identifying non-compliance issues at this stage prevents costly redesigns after production.

Prototype manufacturing is an invaluable tool for identifying design flaws. This proactive approach not only enhances product quality and safety but also improves user satisfaction and reduces the risk of costly errors during mass production.

If you need help with prototype manufacturing, contact us today at Reds Engineering.

Optimized by: Netwizard SEO