Precision Engineering: The Role of Fitters and Turners in Prototype Machining

27 September 2024

Find out the role of fitters and turners in precision engineering and prototype machining, knowing their expertise ensures high-quality prototypes in industries.

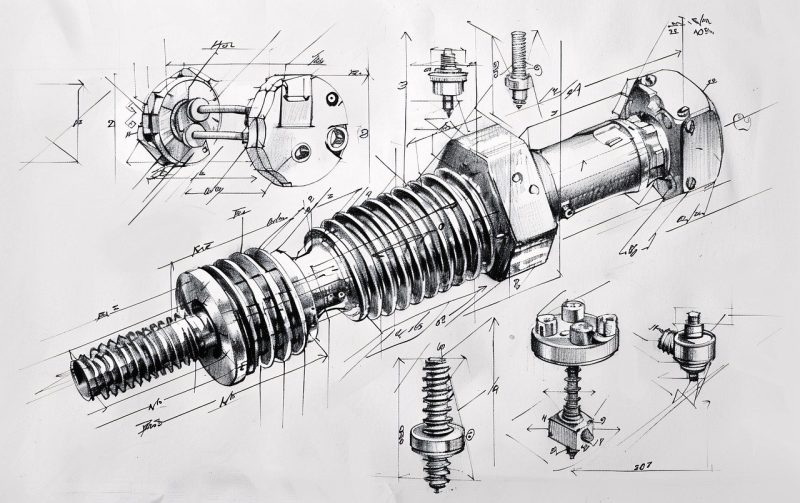

Precision engineering, fitters and turners are important in creating high-quality prototypes essential for product development. Their expertise in interpreting technical drawings, selecting materials, and operating precision machinery ensures that each component is crafted to exacting standards. By turning raw materials into functional parts, they play a crucial role in bringing innovative designs to life.

The Essence of Precision Engineering

Precision engineering refers to the design and manufacture of components with minimal tolerances, often measured in micrometres. This level of accuracy is essential in industries such as aerospace, automotive, and medical devices, where even the slightest deviation can lead to significant performance issues or failures. The journey from concept to finished prototype is a complex one, requiring collaboration between designers, engineers, and skilled machinists.

Fitters and turners are central to this process. Their expertise in working with a wide range of materials, from metals to plastics, allows them to produce components that meet the exact specifications required for a prototype. They work with various tools and machines, including lathes, milling machines, and grinders, to shape and refine these materials into functional parts.

The Role of Fitters and Turners in Prototype Machining

Fitters and turners are responsible for turning raw materials into precisely engineered components. Their role in prototype machining involves several key tasks:

• Interpretation of Technical Drawings: Fitters and turners must accurately interpret complex technical drawings and blueprints. These documents contain detailed specifications, including dimensions, tolerances, and material types, which are crucial for creating a prototype that meets the designer’s intent.

• Material Selection and Preparation: Choosing the right material is essential for the success of a prototype. Fitters and turners have the expertise to select and prepare materials that will perform as required in the final product. This might involve cutting raw materials to size, heat treating them for added strength, or applying surface finishes for improved durability.

• Machining and Assembly: Using a variety of machine tools, fitters and turners shape the raw materials into the components specified in the technical drawings. This process requires a high level of skill and precision, as even minor errors can render a prototype unusable. Once the individual components are machined, fitters and turners assemble them into the final prototype, ensuring that all parts fit together perfectly.

• Quality Control and Testing: Before a prototype can be considered complete, it must undergo rigorous testing to ensure it meets all design specifications. Fitters and turners play a crucial role in this process, using precision measuring tools to verify that each component has been machined to the required tolerances. They may also perform functional tests to confirm that the prototype operates as intended.

Reds Engineering fitters and turners’ ability to transform raw materials into functional prototypes is essential to the success of any product development project. By combining technical knowledge with hands-on expertise, fitters and turners of Reds Engineering help bring innovative designs to life, ensuring that each prototype meets the stringent requirements of modern engineering.

Optimized by: Netwizard SEO